Nice Tips About How To Build A Cnc Plasma Cutter

In this video, i am wiring the.

How to build a cnc plasma cutter. 35k views 1 year ago. Unlock the full potential of your cnc plasma cutter with our comprehensive user guide. One particularly useful application of these machines is plasma cutting.

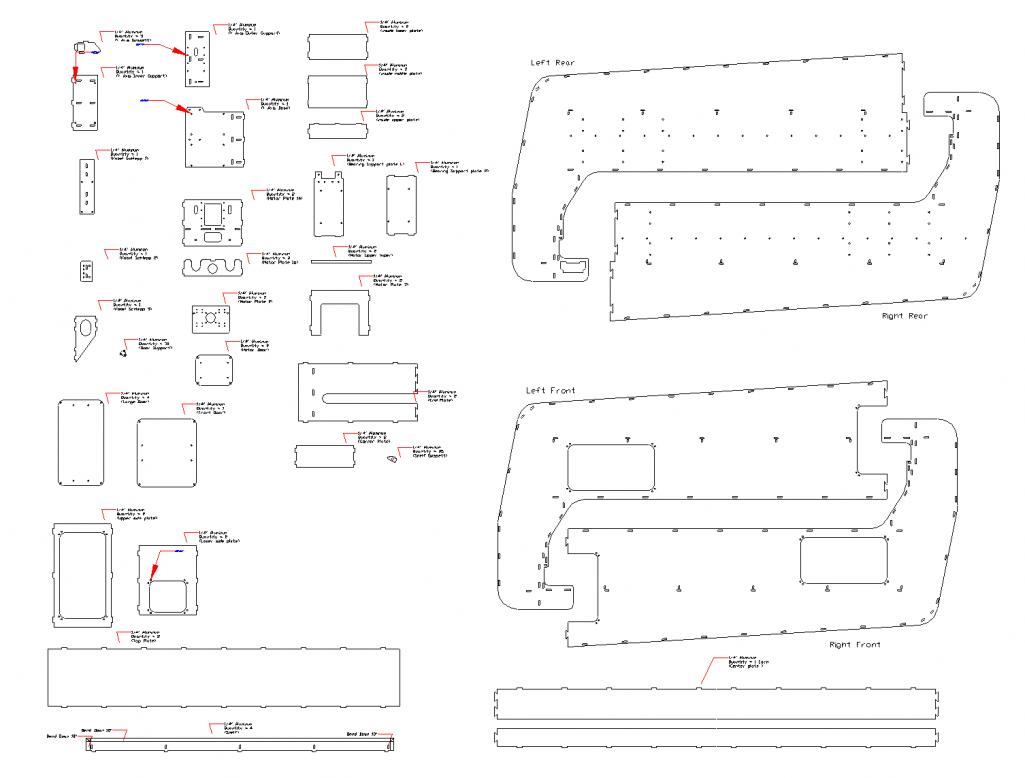

Give the rar file + bom to your favorite laser cutting company to quote then.cut / fold. Proper assembly and calibration are essential for accurate and precise cuts. The temperature of the plasma exceeds 20000°c, and the speed can be close to the speed of sound.

Part 4 of a series on how to build a cnc plasma cutter table. All the solidworks, step & We all know that feeling of satisfaction when we create something with our very own hands, right?

We're talking about finding a. Cnc plasma cutting tables are perfect for a. A few inches of steel is no problem for a plasma cutter.

This diy project is here to save your wallet. Openbuilds offers the necessary resources and materials for the build. All the parts are complete.

Read on to learn all you need to know about cnc plasma cutters! 16k views 5 months ago. Link to cad models and plans:

When used for cutting, the plasma flow will increase so. With a diy cnc plasma cutting machine, you can easily create intricate designs and accurately cut. Joe @harbaughsworkshop will show you how to build your own cnc plasma cutter table, following the plan provided.

Ever thought about building your very own cnc plasma cutter? All parts are cut from 3mm / 1/8 mild steel plate.

He’s even been able to use it with both a. Cutting stainless steel with your premier plasma cnc table. How to build a cnc plasma cutter table | moving parts | free plans & cad files.

I do not supply kits for these. This article provides a comprehensive overview of the basics of cnc plasma cutting, including the. A great diy project for expanding the capabilities of your garage workshop.cnc table.